In the world of firearms customization, there are outfits that follow trends and those that set them. Koted Custom Finishings (formerly Koted Arms) has firmly established itself as the latter.

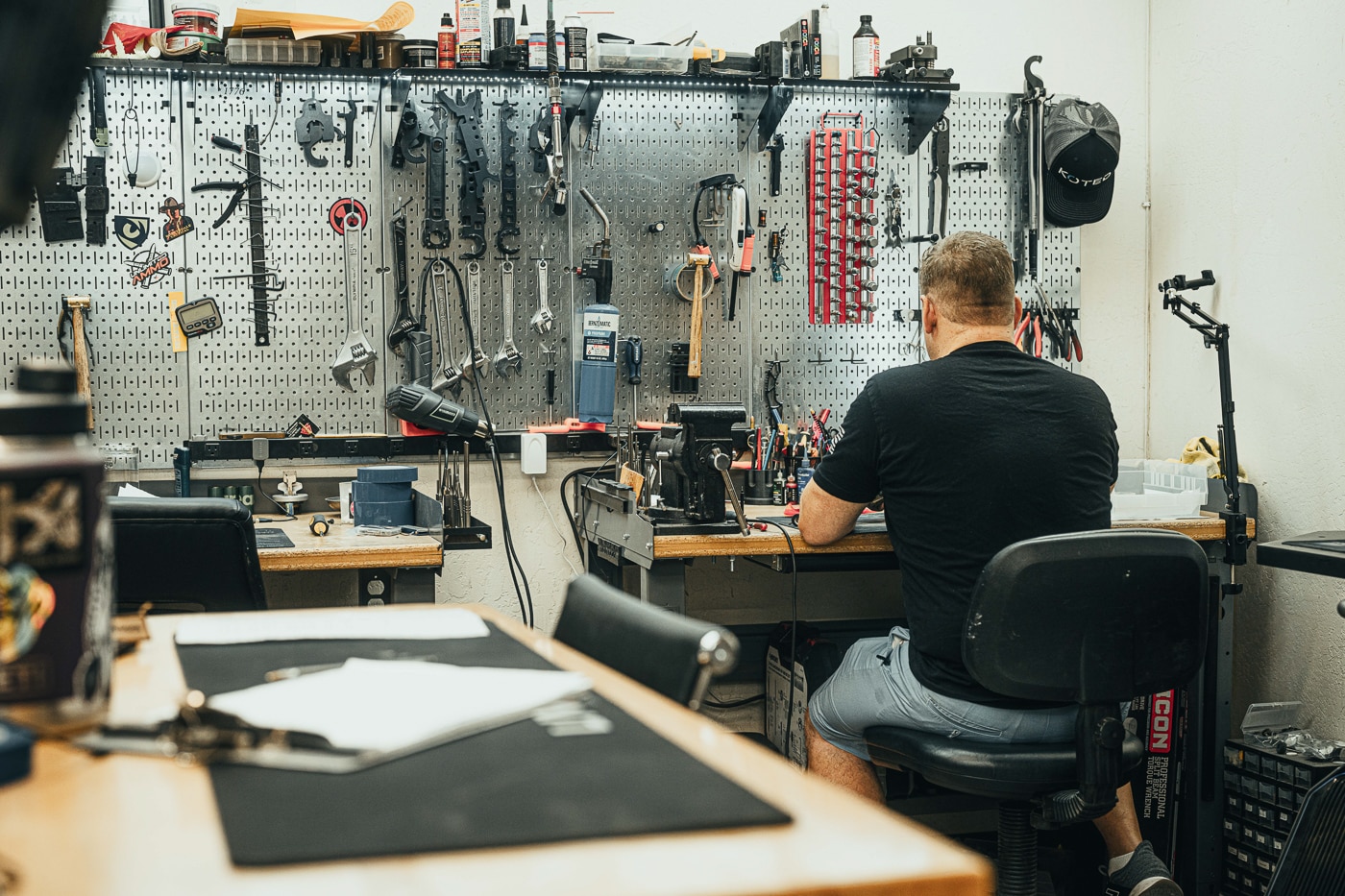

What began in 2014 as a one-man operation focused on Cerakote quickly evolved into a powerhouse of craftsmanship, merging the talents of three professionals with complementary skills: Jonathon DeVries (JD), Steve Gonos and Ben Fine. Today, Koted stands as a premier destination for Cerakote finishing, laser engraving, automated polishing and metal plating, serving firearms enthusiasts while expanding into motorsports, aviation, and beyond.

Their reputation was built on bold, theme-driven builds that grabbed attention: Punisher, Venom, Joker, Iron Man, Spartan warriors, and more. While these eye-catching projects put them on the map, it is their ability to pair creativity with repeatable, scalable precision that has kept them ahead in a competitive market. For Koted, success comes from balancing artistry with efficiency, ensuring the same high level of craftsmanship whether producing a one-off heirloom piece or hundreds of parts on a production schedule.

The team’s story reads like a mix of grit and good timing. JD’s knife work led him to Cerakote finishing; Ben’s experience with powder coating and graphics helped support the creative side; and Steve’s years of laser work was the icing on the cake for complete custom offerings — which brings us to today’s story.

In this exclusive Q&A with The Armory Life, we sat down with JD, Steve, and Ben to learn about their journey, process, and vision for the future.

The Armory Life (TAL): JD, when you started Koted Customs, was it always about firearms, or did the vision evolve into something bigger over time?

KOTED: I launched the business in 2014 with a primary focus on firearms, though we were open to coating anything. The plan was to grow through Cerakote services, but I quickly realized that if we did not push the limits, we would just be more noise in a competitive market. That led us into far more detailed, theme-driven builds, especially using Sharps Bros. lowers like The Jack (skull) and the Spartan helmet. We brought those to life: Punisher, Venom, Joker, pirates, a 300-inspired Spartan, even an Iron Man mask, and those pieces put us on the map.

Cerakote remains essential to what we do, but competition in that lane alone can cap growth. So, we added services that complement each other, including laser engraving and part marking, automated metal polishing, and metal plating. Those investments let us create new looks, handle large volumes efficiently, and they have driven record growth.

TAL: Can you share a bit of the company background and your individual paths? How did each of you arrive here?

KOTED: Koted today is really three strengths, combined. JD started Koted Arms while working full-time in tech sales management. He had been making custom knives and discovered Cerakote while searching for a tough finish. The demand for Cerakote quickly outpaced his knife work, so he committed fully to finishing.

Ben left a corporate tech role in 2014. With a background in powder coating, the move to Cerakote came naturally, and he dove headfirst into lasers and graphic design, studying JD and Steve’s work over the years. The timing was perfect when the opportunity came to merge efforts.

Steve is a proud veteran of the military and the law enforcement community, with more than 20 years of combined service. His respect for firearms and commitment to training led him to launch a business around those passions. As demand for personalization grew, he expanded into custom design and graphics.

He crossed paths with JD, whose craftsmanship fit perfectly, and met Ben around the same time. A turning point came when criminals damaged equipment at Koted. Steve stepped in to help, an act that sparked the collaboration which eventually united their three paths into one company.

TAL: With three of you — JD designing and coating, Steve engraving, Ben running ops — how do you keep a unified vision?

KOTED: JD is the process architect. He creates new looks and builds the repeatable processes that let us execute at scale. Ben is the glue and the face of the business, overseeing sales, operations and shipping. Steve is our design and laser expert, second to none at creating engraved details that truly differentiate.

Because each role is essential to the whole, we are in constant communication about needs and expectations. Regular check-ins help us handle immediate priorities, plan ahead, avoid big obstacles, pivot quickly, and most importantly build trust so decisions align with our goals.

TAL: How do you keep an edge when the space is crowded with trend-chasers and stencil slappers?

KOTED: Our offering is genuinely unique. Plenty of shops can produce a one-off showpiece. We pride ourselves on not only pushing new looks, but also delivering them at scale. There is a huge difference between nailing one over-the-top build and doing it 500 times — all while keeping quality high and turnaround competitive. Our reputation is built on doing both.

TAL: You started in firearms, but now motorsports, aviation and tech are calling. What is driving that cross-industry demand?

KOTED: Breaking into new spaces is challenging, but great customers and strong referrals have driven most of our growth beyond firearms.

TAL: When a new industry approaches, what is your litmus test so it does not dilute the brand?

KOTED: We invest the time to understand the customer’s needs first. That clarity helps us choose the right process, set expectations, flag any limitations, and scope the full relationship. There is always a give/get. A company sending 5,000 parts a month will not have the same unit economics as someone sending 15. We are transparent about that so both sides win.

TAL: Will firearms remain the flagship, or is broader custom culture becoming the core?

KOTED: We let the market decide. We love firearms, but our passion is finishing, delivering the final look on the things our customers care about. Diversifying also helps hedge against the cyclical nature of different industries.

TAL: Ben, how do you align with partners who respect your standard of craftsmanship?

KOTED: We look for brands that value the details, communicate clearly and collaborate through the process. When a partner cares about doing things the right way, we can tailor the product and service to their application and hold ourselves to the standards our name stands for.

TAL: What piece best captures the Koted ethos? What is the biggest creative risk that paid off?

KOTED: It evolves. Early on, it was theme guns like Punisher, Venom and Iron Man. Later, it was detailed laser work with creative color isolation that was uniquely ours. Most recently, combining polishing, plating, laser work and Cerakote into cohesive builds has set us apart. The biggest risk that paid off? Investing in people. Our team is what lets us push limits, get creative, and execute.

TAL: From raw metal to finished masterpiece, what is your typical process when a new project hits the bench?

KOTED: It starts with the customer, deeply understanding what they want. Then we assemble the right specialists, brainstorm a direction, and each person executes their piece of the plan.

TAL: Cerakote is not just color, it is chemistry, branding, storytelling. What separates a Koted piece from surface-level work?

KOTED: Like choosing a tattoo artist, customers pick us for our style, quality and reputation. We are not trying to be everything to everyone; we are trying to be exceptional at what we do best.

TAL: Steve, on laser work: how do you balance restraint vs. boldness, and ensure durability and performance?

KOTED: Legibility beats complexity, especially on tight canvases where fine detail can get lost. Negative space lets a design breathe. Contrast matters across Cerakote, plating, etching; each has different depth and visual characteristics. Purpose matters, too: keepsakes and awards can carry more delicate detail, while duty-oriented firearms often benefit from bolder moves.

Performance is non-negotiable. Aesthetics must never compromise mechanical safety, tolerances or required legal markings. We treat critical areas with special care. There is no impact to headspace, lockup, pressure or wall integrity. We have mapped heat ranges and process parameters so we do not affect metallurgy, and we have built settings that keep us inside those tolerances. In non-critical zones, such as AR magwells, deeper cuts are an option.

For clients who only know they want something “insane,” we help them find a direction. We talk about passions such as history, gaming, warrior culture, and review reference images together. Once there is a focus, we align on budget, since what is considered “over the top” varies. The goal is the best bang for the buck and a result worthy of being an heirloom.

TAL: For a shop known for bold customization, what does it mean to be featured in this The Armory Life spotlight?

KOTED: We are humbled and honored to be highlighted. We are regular guys doing what we love, proud of what we produce, and grateful others feel the same.

TAL: Can you give us a peek at the custom Prodigy 9mm you are building right now? Can you describe both the concept and the boundary-pushing details?

KOTED: Isaac at Fourged Group asked for a traditional pirate theme and wanted a statement piece. We went all in with a fully wrapped two-tone plated finish, every surface polished, and tucked-away Easter eggs that reward a close look. It is bold without being gimmicky, cohesive, handcrafted, and unlike anything we have seen on another Prodigy.

TAL: Favorite Springfield platform, past or future?

KOTED: We have worked on most of Springfield’s offerings and are consistently impressed with their quality and attention to detail. We love the Echelon for its aggressive styling and cuts, but our favorite to work on is the Prodigy. Performance-wise it is one of the best values in its class, and the big, open, flat surfaces are a dream canvas.

TAL: What is next for Koted Custom Finishings? More collaborations, more industries, or diving deeper into firearms?

KOTED: All of the above. We have collaborations in the pipeline (we cannot share details yet), we are in talks with companies outside firearms, and we are acquiring new machines to expand one-of-a-kind, industry-leading finishes while boosting volume capacity. The future is bright. We will keep pushing limits.

TAL: Is there anything we have not touched on that you want readers to know?

KOTED: Just our passion for custom work. Whatever the industry or idea, we love bringing visions to life, from the smallest personal project to the largest production run.

Closing Thoughts

Koted Custom Finishings represents the best of what firearms customization can be: artistry backed by discipline, innovation balanced with consistency, and vision supported by execution. Their ability to craft one-of-a-kind builds while scaling production has made them a leader not just in firearms, but in the wider world of custom finishing.

Whether it is a pirate-themed Springfield Prodigy, a fully plated 1911, or a fleet of laser-engraved components for another industry, Koted pushes the boundaries of what is possible without ever losing sight of quality. For shooters, collectors, and anyone who values craftsmanship, Koted Custom Finishings is a name to watch.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!

Join the Discussion

Featured in this video

Read the full article here